Technology, Speed, Team Spirit: How Automation Creates Space for Creativity

Efficiency, precision, and a passion for large-format printing – for 15 years, Michael Haider has ensured that creative ideas at TREVISION are transformed into impressive projects. From his early days in prepress to leading production planning, he has experienced first-hand the evolution from analog processes to fully digital workflows. In this interview, he explains how automation enhances quality, why technology continues to inspire him, and what fascinates him about his work.

When you started at TREVISION 15 years ago as a graphic designer, you initially worked in prepress – the interface between design and production. What has changed?

A tremendous amount. Then as now, the greatest challenge lies in translating creative ideas into technically flawless print data. We ensure that a concept becomes an error-free, production-ready product.

Since autumn 2025, you have been heading production planning. How has this influenced processes at TREVISION?

Production planning is the backbone of on-time and resource-efficient operations. I review every order for feasibility, capacity allocation, and machine availability. Only after my approval does it move into production. My day begins with a digital job list, which I check for plausibility and available resources. Only then is the order confirmed by the internal sales team. This ensures that large-format printing projects are delivered on schedule and at the highest quality standards.

TREVISION is known for innovative processes and has been driving digitalization and automation for years. What role do they play in project implementation?

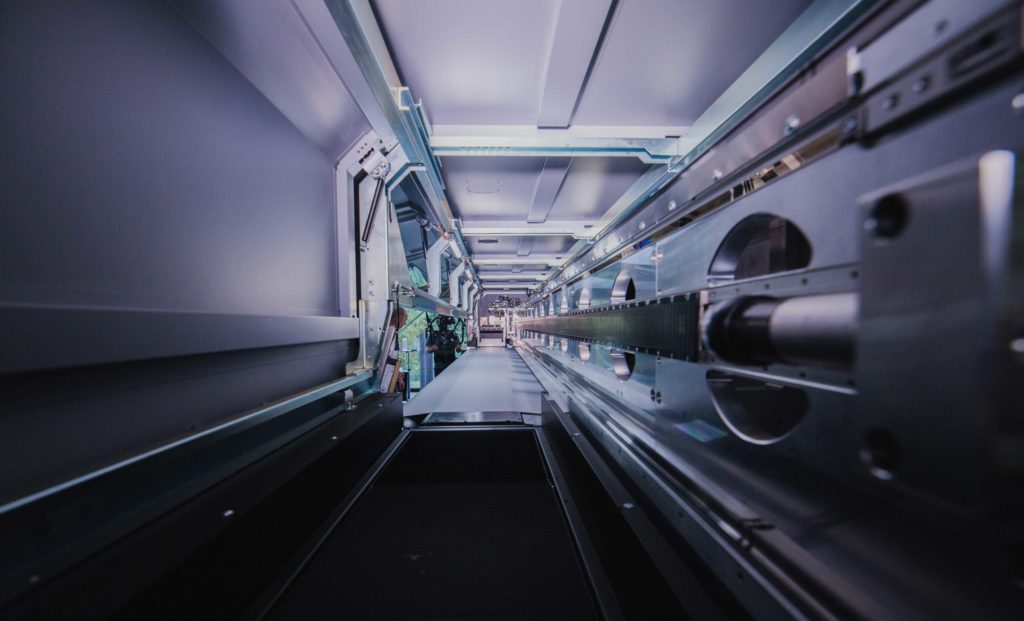

A crucial one! Together with Durst and Advanter, we developed a customized workflow that automates every step from data intake to print approval. Print files are automatically checked – resolution, color mode, format – and errors are detected instantly. As a result, 80 percent of the workload has become significantly easier. For our clients, this means: through automation, we have been able to free up internal resources. Our team now has more time for our core business – developing innovative solutions. We can focus more strongly on creative concepts, new materials, and tailored client projects instead of manually handling routine processes.

Despite automation, where do limitations still exist and where is human expertise still essential?

With all products that are “out of the ordinary” – such as angled constructions, cut-outs for complex exhibition stands, or highly specialized productions like the wrapping of Vienna’s Ringturm. In such cases, automation still reaches its limits.

How does production planning contribute to saving resources and increasing efficiency?

We precisely schedule when each visual is printed and bundle jobs in a way that reduces material waste. This means: fewer linear meters, less waste, greater sustainability. Our digital workflows enable us to intelligently combine print data and manage processes so that quality and resource efficiency go hand in hand.

Many! The DHL project, where we designed the elevators to look like shipping containers from the outside, was fantastic. The window graphics with selective white printing for Philip Morris and the Ringturm building wraps are also highlights. One of my very first projects was a light ceiling installation in Oslo in 2011. The suspended ceiling was printed with an artwork by a Swiss artist and then backlit. I only saw the design in prepress and later in photos – and I was truly impressed by the effect.

After so many exciting projects: What makes your work personally special to you?

The variety! No two days are the same. And the feeling of seeing a finished project and knowing: “We created that.” When I’m walking somewhere in Italy or anywhere else in the world and spot something we’ve printed – that’s the greatest reward.

Speaking of Italy: there’s an espresso machine in your office …

I love a good espresso – but 99 percent of coffee machines in Austria aren’t calibrated to produce a true Italian espresso. Once you’re used to the original, it becomes a challenge. So I simply decided to install my own espresso machine in the office.

Finally: You’ve been working in advertising technology for 15 years now – what’s your conclusion?

Printers today offer higher resolution, color reproduction is more brilliant, and we work with innovative materials. Processing times are minimal, and computers are faster. Particularly impressive is our Durst RHO 350 HS – the machine’s quality and speed are outstanding. Digital cutting systems are also extremely robust and precise. All of this makes production more efficient and more sustainable.

What hasn’t changed is the time pressure – it’s simply part of the advertising industry. If you don’t handle stress well, this isn’t the right field for you. But with a great team like the one we have at TREVISION, it’s truly enjoyable.

Where do you find balance to offset that time pressure?

By playing billiards. I started playing regularly again about a year and a half ago, and I really enjoy it.