Let’s green up! Challenges and pathways towards a greener industry

Writing “green” on your portfolio? Easy. But actually making a change? It’s crucial to know the difference. Read on to find it out.

Getting green: What’s the challenge?

Let’s be honest: a lot of “greening” is mainly, well, marketing. Offering a product line with a focus on sustainability? Fine, but what about the remaining assortment? Introducing alternative materials? Fair, but is “alternative” synonymous with “green”? Measures of this kind sound promising but often stay superficial. The real challenge is to look beyond empty words. And to actually make a change.

We’re also in textile print industry, as you know. An industry that is mostly built up on synthetic fibers. The issue: these PVC materials are not biodegradable. They don’t decompose. And that’s why the pressure to switch to alternative materials is growing. Recycled materials, for example. Sustainable fibres and cloth that reduce our ecological footprint.

But such materials aren’t easy to develop. Due to their different composition, they’ve got different properties – and consequently, they’ve got to be processed differently as well. This necessitates a lot of testing, and testing is expensive. Textile manufacturers won’t invest in it just because we demand it. Our sector is in the range of a few thousandths – the majority of textiles are produced for the clothing industry. It’s them who’ll have to drive innovation. Only then, manufacturing will change.

Step by step towards a greener industry

Does this mean that we’re just sitting back, waiting for the clothing industry making their move? — Of course not. We’re continuously working on doing our bit. The bit that we can contribute to making a greener world.

Some steps we’ve already taken. We’ve got a whole range of alternative products – recycled materials for our textile frames, for example. Or truck tarpaulins that are free from PVC. We’re testing with wood fibers and organic cotton, and we’re in constant communication with our subcontractors to enhance sustainable development.

The goal may be ambitious: for every application we offer, we aim to have a green alternative. Starting point? Next year, first quarter. But we’re confident we’ll get there in time: We’re constantly on the lookout for new “green” products, and we’re in touch with environmental organisations to ensure we make the right choices.

Greening through digitalisation

But there are less obvious ways of getting greener, too. Ways that take a step away from producing new materials. Ways that focus on reducing resources altogether. One possibility of doing so is by optimising the ordering process. Why? Because ordering too much isn’t only more expensive for the client. It also results in overproduction, and consequently uses up more resources – something we seek to avoid.

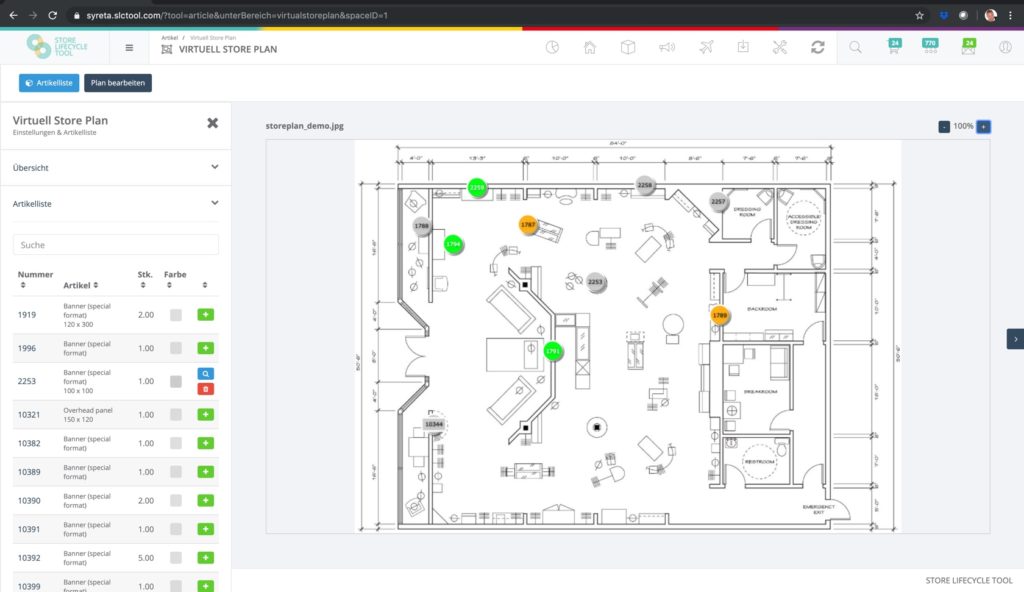

Our digital management system allows clients to order more precisely. A specialised software, both cost-effective and environmentally friendly. It helps avoid an unnecessary waste of resources, regarding both production and delivery. This “greening” may not be as visible, as self-evident as a label blatantly saying “sustainable materials used”. But it works towards the same goal. And it’s this accumulation of steps, as different as they may be, that will lead us to this common objective. You just have to get creative. And that’s what we love to do.